Distribution Center Best Practices.

Top 10 Best Practices that You Can Implement in Your Distribution Center Tomorrow with No System Changes and Very Little Process Changes

Implementing best practices in your warehouse is the key in increasing the throughput and productivity. They are listed below. 1. Assign Ownership of Aisles to Operators So They Keep their Aisles Clean with Pride Managing the operator’s aisle pristine and in an orderly way is necessary to increase the picking in the warehouse. When operators are happy and proud of the work they do – they do even better. To make them proud of the…

The Zone Picking Best Practice to Improve Order Picking Productivity

This next best practice is about the warehouse zone picking process. The way this works is if your picking involves going to multiple areas, multiple isles of bin locations, and you are picking from different bin locations. This process is about eliminating all the unnecessary walking, and of course we all know the more you pick, the more you can ship, the more you ship, the more you invoice, the more you can get paid….

The Warehouse Yard Management Best Practices to Increase Visibility

This is a best practice that will be very useful if you have a lot of trucks, trailers and containers coming into your facility. This is called yard management, so basically this is a small system within the WMS with which you can track your truck’s trailers and containers. You can create yard locations and of course you can create dock doors and you can track them exactly. But it’s all about visibility right, I…

The Warehouse Voice Picking Best Practice to Improve Efficiency

This best practice is on warehouse voice picking. Instead of looking at the screen and looking at the device and typing in the characters and picking you would talk hands-free and eyes-free with voice-picking. This is what the voice picking is, but let’s take a step back and understand how this whole picking process is evolved. If you look at it, the very first picking process was all based on the paper pick takers. There…

The Best Practices to Implement Vendor Compliance in Your Warehouse

This next best practice that you can implement in your distribution center is something called vendor performance. So vendor performance is basically you as a retailer or a distributor or as an ecommerce order fulfiller you are buying your product from different vendors. When the vendor ship to your DC, you can rate them on how well they are doing in terms of compliance. Compliance requirements are mandatory in all of the big ecom warehouses….

The Best Practices to Optimize Slotting Process in Your Warehouse

This next best practice is about optimizing your slotting process. It’s all about picking and especially it’s even more important in the e-commerce world, because you are picking one unit order and two unit orders. This is what the standard order profile is for the orders that people are placing from their computers at home through the web and through the mobile device. It’s all about picking from the active locations and piece pick locations….

The Returns ASN Best Practice to Optimize Reverse Logistics in Your Warehouse.

This best practice is about Returns ASN (Advance Shipment Notice). We discussed about the ASN before and we articulated on how useful was the ASN in deployment scheduling and your were able to plan your work in the receiving area. You were also able to get upfront information as to what is going to hit your DC and you could even allocate inventory in terms of the location of the product and allocate inventory for…

The 3 Best Practices to Optimize Your Warehouse Inventory Replenishments

This best practice is about making replenishments inside the warehouse. It is important to stay on the top off replenishments always in your warehouse. If you have just one shift that you are running it would help a lot. If you spend extra hours in the evening and then do the topping off all your active locations it will be helpful for the pickers in the next shift. In the next morning when the pickers…

The Warehouse Rate Shopping Best Practice to Reduce Shipping Charges

This best practice we are going to discuss is called as rate shopping. The rate shopping can be done for both parcel and the (Less than Load) LTL. I mean the parcels are the small boxes that they ship mostly as Ecom orders. Sometimes they also ship retail orders as parcels from the distribution center to the final destination. In Ecom orders it will be a consumer that’s buying product, they place an order on…

The DC Quality Control Best Practices to Improve Shipping Efficiency

This is a best practice that you can refer to if you have a lot of quality issues in your distribution center. Let us assume that for some reason you opened up the box from reserve. You thought that everything was okay at the time of receiving. Then you put it away in reserve and for replenishment you moved the product from reserve to active location. After opening up the box you find that there…

The 3 Best Practices to Run Effective Warehouse Meetings

This best practice is about running the warehouse meetings effectively. It’s basic and I learnt a great deal from consultants and doing consulting myself, the consultants gets billed at a high rate. For eg. I have been to sites where I got billed and the value we brought to the table as a team and it was always highly challenging. The complicated problems we solve for them and imagine one hour of my time is…

The Sequencing Best Practice to Boost Warehouse Order Picking Efficiency

This best practice is known as location sequencing. It means that when you are configuring your locations for picking purposes, replenishment, and for put-away purposes in the reserve area in the top level position. While doing this you would have picked the naming convention to streamline the picking. On top of it there is also the ability to configure something called as the location sequencing. It means that you do not want your pickers to…

The Best Practices in Measuring Warehouse KPIs for Enhancing Productivity

This best practice is about measuring and improving warehouse productivity through LMS, which stands for labor management system. There are typically two segments of customers that will benefit significantly from an LMS, one is this huge ERP – vendor who supplies WMS. For example we will take SAP. SAP’s core was ERP and they still developed and integrated the WMS because many of their customers have integration challenges with other platforms. They gave them the…

The Best Practices in Designing UI/UX of the Warehouse Management App

This best practice is about the importance of UI (User Interface) in improving the distribution center productivity. In this day and age where Apple and Android have completely changed the user experience that is so easy to understand and use the app. Particularly in the distribution center the time is spent significantly on training the end users. I’ve seen many distribution centers that are literally revolving doors, where personnel come and go. All these personnel…

The 4 Best Practices in Designing a Perfect Global Distribution Center

This best practice is called “implementing global design in the distribution center”. Let us say when you go to Walmart in Atlanta it looks one way and then let’s say you go to Walmart in Cincinnati, Ohio it looks completely different. It will be difficult fit for you to navigate to get even a simple cough syrup that you want to pick up. It will be much easier by the fact that if all the…

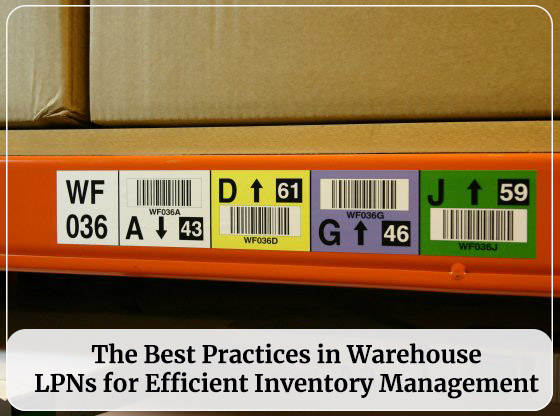

4 Best Practices in the Inventory Management through LPNs

This best practice that you implement in your supply chain is to Keep Track of Stock Movements through LPN (License Plate Number). You can make it a rule in your in your DC (Distribution Center) that any product which may be just one unit or two units or three units whatever it is any product, group of products, any set of products that you’re moving always gets an LPN. LPN could be even called as…

The 5 Best Practices in the Directed Putaway to Improve Productivity

This warehouse best practice is called the directed putaway. Putaway is a process of moving the product after receiving at the receiving dock. The product gets received and either cases were built or the pallets were built and now these cases and pallets have to be put-away in their reserve location. The way it works is the product is moved from the receiving area to the reserve area in so many different ways. The user…

Top 4 Best Practices in Dimensioning of SKUs with Benefits

This best practice is about something called dimensioning of SKU’s in warehouse. Dimensioning of products is done by capturing the length width and height of the products.

The Best Practices in Cross-docking with Benefits

This distribution center best practice is called the cross-docking. Cross-docking is basically sending a product you are sending from one dock to another dock i.e. from the receiving dock to the outbound shipping dock directly without any intermediary processes. Cross-docking makes it so much efficient because you don’t have to send it to the reserve and then again from reserve to the active location and then pick from the active location. In the cross-docking process…

Why You Need Cartonization in Your Fulfillment Center?

If you are looking to upgrade your WMS or if you’re getting a new WMS or switching to another WMS or if this is your first time WMS, here’s the another feature to consider. This feature is called cartonization. Cartonization is done among the different carton box sizes that you have for your order, whatever items that are being shipped in that order, you find the smallest box that will hold these items of the…

The Best Practices for Implementing Advanced Shipment Notice (ASN)

We’re going to discuss another best practice that you can implement in your distribution center (DC). These practices need some more work to implement, like you have to design your systems, your process and so forth. This is not something that you can implement tomorrow or day after tomorrow, without process changes, systemic changes. But this is good to know because when you’re upgrading next time or when you’re implementing a brand new WMS for…

Best Practices in Warehouse Dock Door Appointment Scheduling

Another best practice that you can implement in your distributions center is something called appointment scheduling. So basically what this means is when the truck drivers are arriving to your DC or when when they’re about to come to your DC they call ahead through their transportation companies and say “hey please give me an appointment, and I’m going to be there at this time, this date”. Booking the appointment makes it easy to make…

5 Best Practices in Optimizing the SKU Velocity in Your Warehouse

This post is about the best practices to track the velocity of your SKUs which is important to know as a DC manager and as a director of DC. As a supply chain inventory manager of your supply chain you got to know what are your A SKU’s, what are your B SKU’s, what are your C SKU’s. A SKUs are the fastest moving SKUs and the B SKUs are the moderately moving SKUs and…

1. Increases EPP, using budgeted line items.

1. Increases EPP, using budgeted line items. Millennial friendly technology, less onboarding time, very easy adoption – touch screen keypad, and 43% of Millennials already use IOS, familiar with Facetime, 85% of Millennials aged 18-24 own devices and 86% aged 25-34 own them, consume a lot of video on their smartphones, and are highly comfortable with this medium, they understand and like apps.

Millennial friendly technology, less onboarding time, very easy adoption – touch screen keypad, and 43% of Millennials already use IOS, familiar with Facetime, 85% of Millennials aged 18-24 own devices and 86% aged 25-34 own them, consume a lot of video on their smartphones, and are highly comfortable with this medium, they understand and like apps.